What is the Insight Controller?

The InSight Controller works on a Windows IoT-based open architecture platform and has an EtherCat-based I/O system, which increases the speed of communication between the machine and the controller.

InSight Features

- Operates using laser technology to measure both distances for plate skewing and torch height

- Monitors movements in real-time and makes corrections

- The robust enclosure has proven to handle harsh shop environment

- Built-in USB ports for file transfer

- Built-in Wi-Fi capabilities

- Joystick for manual machine jogging

- Emergency Stop

- Single or Dual 22' Industrial ELO Touch screen LCD

- Pedestal stand for controller

- Interchangeable components

Revolutionary New Controller Design

Decades of experience and dedication went into designing a new controller that will break the mold of traditional steel processing by allowing for more possibilites than ever before. Our controller offers multi-torch cutting, drilling, and 5-axis bevel cutting with the capability of expanding to even more processes. With an interactive 3D interface that's uniquely designed for each specific machine, you can view machine progress and diagnostics in real-time.

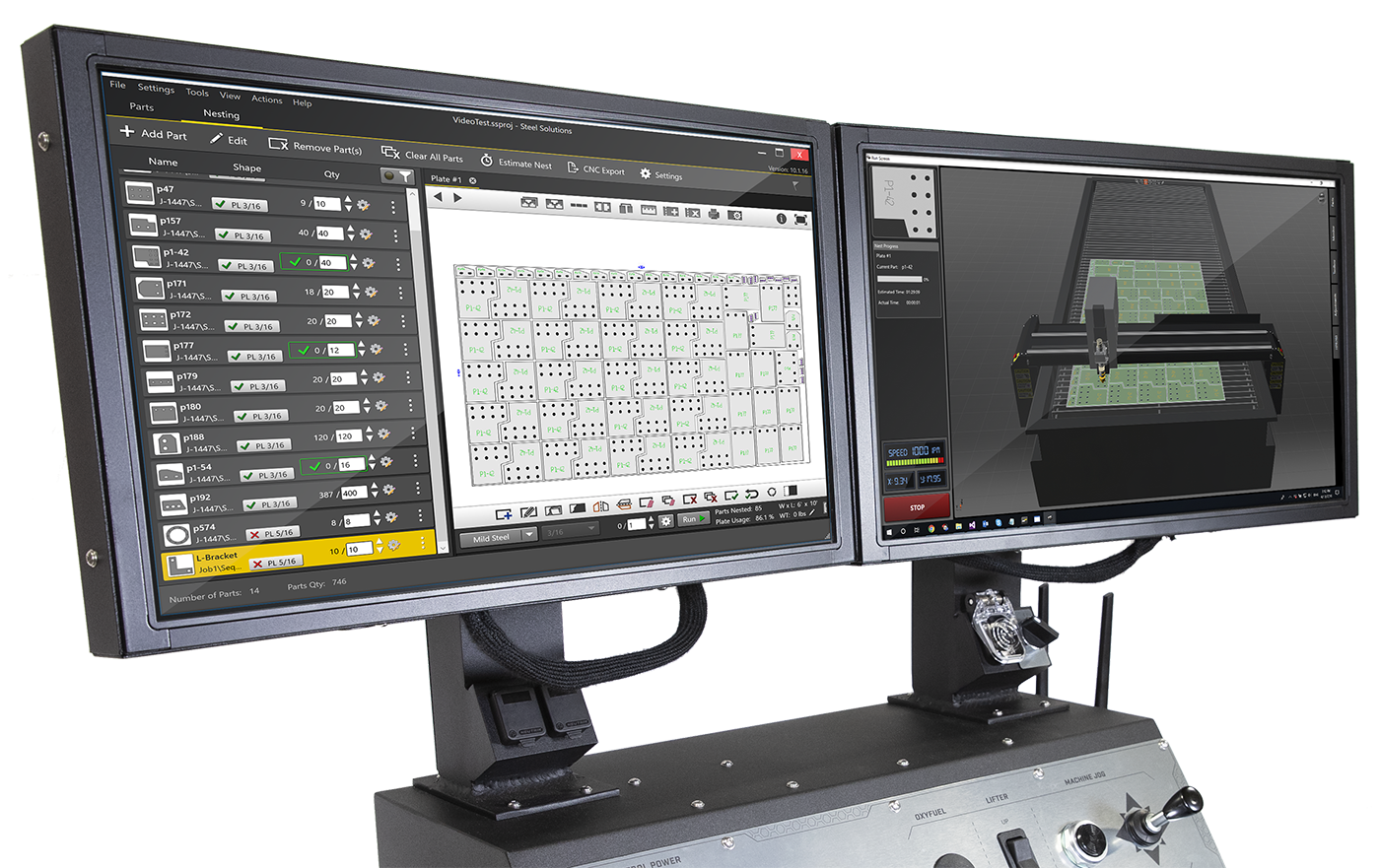

Next-Gen Software

The InSight Controller comes equipped with our powerful Steel Solutions™ nesting software and our advanced machine controller software, featuring a plethora of nesting options, real-time 3D machine interface, full CAD/CAM editing package, and much more!

Steel SolutionsAdvanced Machine Software

Full 3D Environment

Three dimensional recreation in real time of machine, it's operations, and nest being cut.

Advanced Laser Mapping

With the accuracy of our measuring laser, complex 5-axis bevel cuts are easily achieved, along with the ability to process and cut structural material.

Jump to Part Processing

With the ability to skip parts, mark parts as complete, and jump to specific parts in the nest, operators have complete control over cut orders, in order to meet certain production requirements on the fly.

Temporary Marking Solutions

If you are in search of a way to speed up production, lower labor cost while improving worker safety, and efficiently keep track of part numbers, job numbers, etc. whether you need a single-dot or 16-dot, our systems can handle the most complex of your plate marking needs.

Choose Single-Dot or Multi-Dot to Learn More

Ink Markers

Quickly Visualize Part Layouts

Mark Part Numbers & Job Numbers

Lower Labor & Improved Efficiency

Easy Ink Cleanup With Acetone

Ink Markers

Quickly Visualize Part Layouts

Mark Part Numbers & Job Numbers

Lower Labor & Improved Efficiency

Easy Ink Cleanup With Acetone

Permanent Marking Solutions

When an economic and efficient permanent marking solution is desired that can even work with hardened steel and is still visible after galvinization processes, the Dot Peen system could be the answer you are looking for.

Dot Peen Marker

Reliable, Economic, & Efficient

With the use of only one consumable(Stylus) and without the need for other materials such as used in ink markers, the dot peen marker is an excellent economic choice for your marking needs. Capable of marking part numbers, heat numbers, etc in a matter of seconds.

Full 360° Marking Capabilities

Capable of marking at angles from 0° to 360°, solving problems with difficult and unconvential diagonal marking solutions.

Adjustable Force, Speed, & 'Quality'

With fully user adjustable paramaters for force, speed, and quality, the Dot Peen marking systems allows you to streamline your workflow for different materials and sizes of characters based on the job at hand.

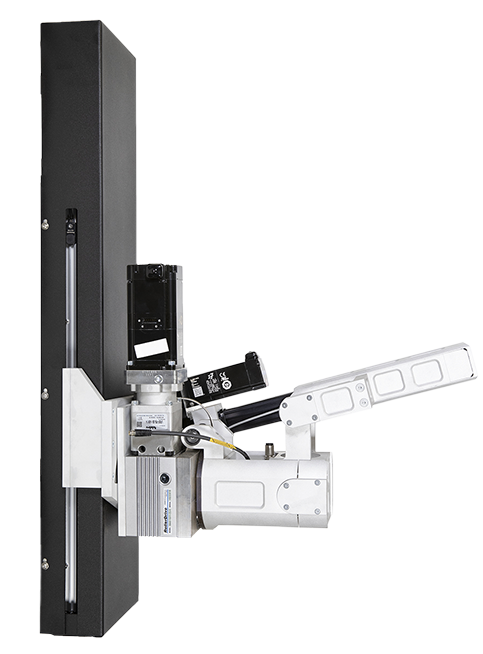

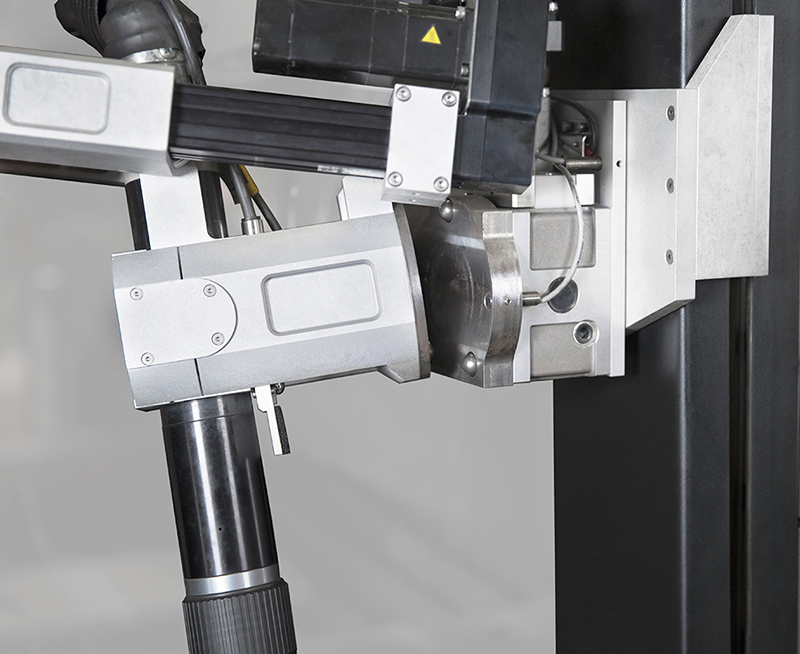

5-Axis Torch Beveling

Our compact 5-axis plate beveling unit gives the plasma torch a full 360 degree range of motion. When designing this system, our goal was to build an industrial quality bevel-head that would expand beyond the capabilites that are typically offered on a plate cutting machine.

Robust Bevel Lifter

Designed for the high-speed and precise movements that are required for beveling applications, our robust bevel lifter takes height control to another level. This lifter is built to handle the tough demands of production bevel cutting.

- Bearing design and preload for beveling application

- Gravity compensation pnematic counterbalance

- High speed to get that torch to the next orientation

Crash Detection System

One of the unique features of this revolutionary design, the entire assembly is protected by a magnetic-mounted crash detection system.

This system protects both your valuable equipment and people operating the machinery.

Dual-Bevel Capabilities

Unlock the potential to double manufacturing throughput with dual-plasma torch capabilities. With the ability to incorporate multiple beveling torches, you can push your production to the next level.

Oxy-Fuel Compatibility

Introducing our oxy torch plate beveling system! This system uses an interchangle torch design with an adapter for the bevel unit.

- Easily Cut Thicknesses Well Beyond Conventional Plasma

- Wide Variety of Bevel Cuts: Simple to Very Complex

- X-Bevel, Top-Y Bevel, K-Bevel, and Many More...

- Excellent Cut Quality

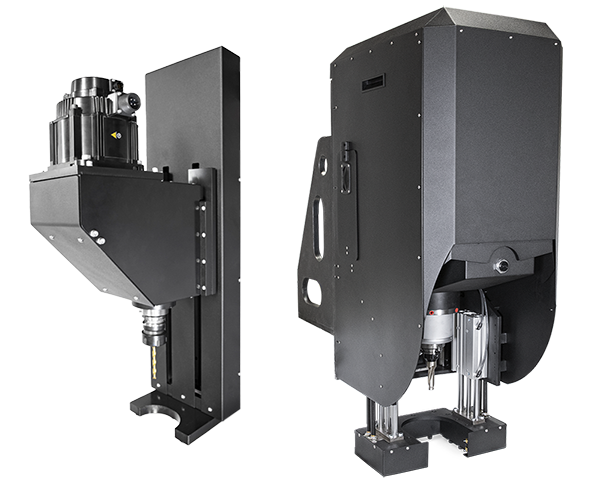

Drilling Options

Our new drill system line-up includes 2hp, 10hp, and 20hp units. Our extremely versatile drills process high quality parts by utilizing carbide drilling, helical milling, and rigid tapping abilities.

Our New Drill Line-Up

Our new drill system line-up includes 2hp, 10hp, and 20hp units. Our extremely versitile drills process high quality parts by utilizing carbide drilling, helical milling, and rigid tapping abilities.

Carbide Drilling

Precision carbide drilling gives you accurate holes even for the lowest tolerances. Our 10hp unit drills up to 1-1/2" diameters with proper tooling.

Helical Milling

Process accurate slot and counterbore operations with consistent results every time using the helical milling feature.

Rigid Tapping

Rigid tapping synchronizes feed and rotation to give you smooth bolt-ready holes with clean threads from start to finish.

Angle Cutting

With precision laser scanning to establish a datum, you can be sure that repeated cuts are accurate. From straight cutting, beveled cutting, slots & notches, miters, coping, etc, all your angle cutting needs are covered with our system.

Pipe & Dome Capabilities

With advanced laser mapping, sophisticated motion control, and multi-axis beveling, get ready to push beyond what was previously possible in the realm of pipe processing. With our system, you can easily achieve beveled holes, miter end cuts, saddle cuts, lateral nozzle cuts, and more!

Want the very best in servo motion? Yaskawa's new Sigma 7 servo system is pushing motion to a whole new level. Sigma-7 is engineered to bring new responsiveness, reliability and effectiveness to the automation that powers your productivity. The Sigma-7 family of rotary, direct drive and linear servo products continue the legacy of the Sigma series, which has set the standard in innovation and reliability for a quarter century.

- Smooth and Precise Allowing for High Quality Parts

- Reliable and Durable to Give Consistant Results

- New Sigma-7 Servo Package Offers Next-Level Motion

- Vibration suppression,anti-resonance compensation

- Friction model compensation and ripple compensation

Additional Add-Ons

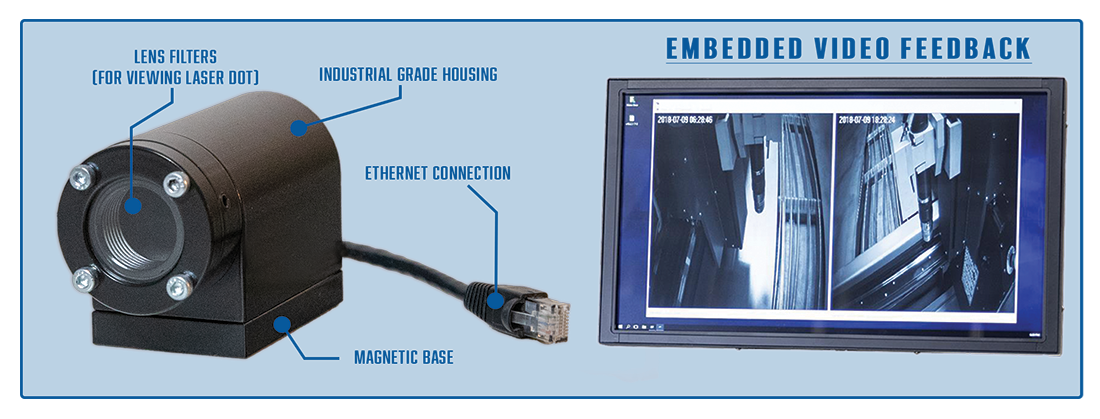

Machine cameras are especially useful when the controller is mounted off the machine. Embedded video feedback is great for tracing remnants, machine monitoring, and diagnostics.

Click HereATek Machine Tracker Software

CNC Plasma Burn Table Production Monitor

With the ATek Machine Tracker software, all aspects of your production are capable of being directly monitored in real time. With a live camera feed of your machine, real-time machine event log, comprehensive machine history that can be exported to PDF, and customizable workday hours for accurate production/setup/idle machine statistics, your production will be back on track with the ATek Machine Tracker.

MACHINE TRACKER

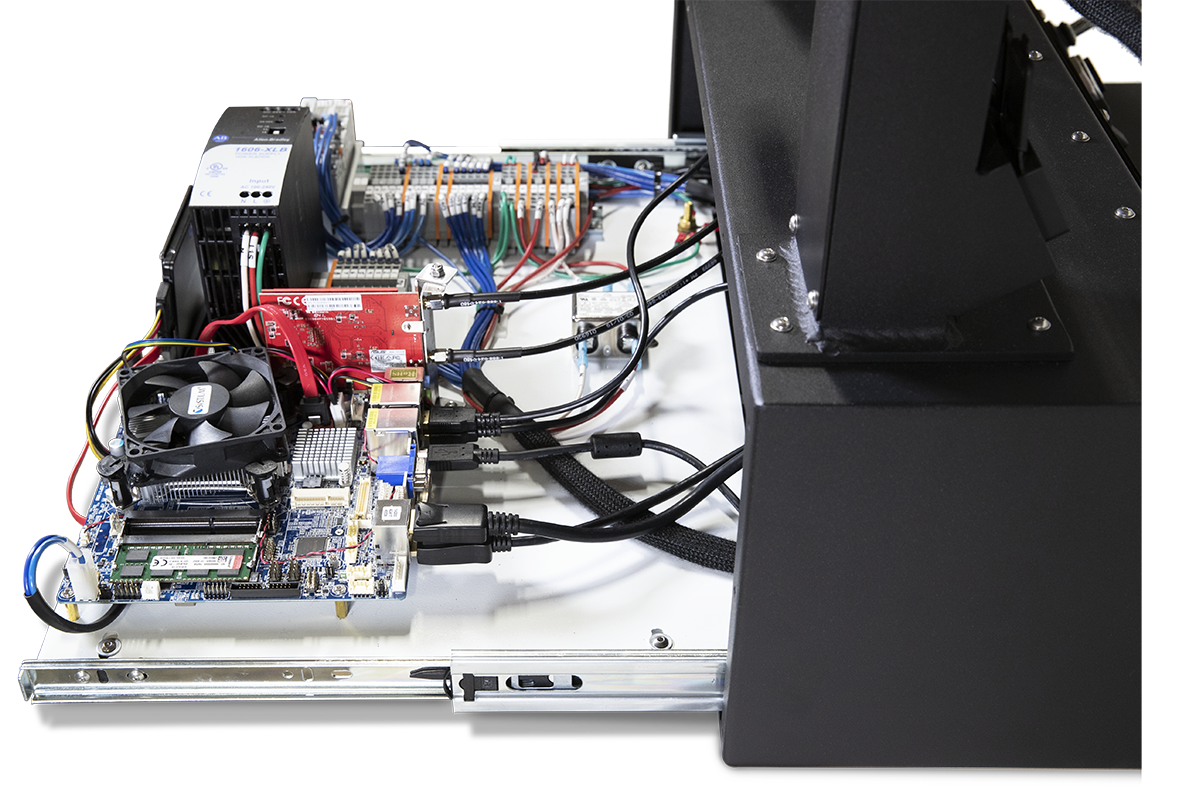

Slide-Out Components

The slide out panel, which is unique to our console, simplifies any repairs or upgrades that may need to be done on the controller. If necessary, the entire panel can be quickly swapped out to easily handle upgrades in the future.

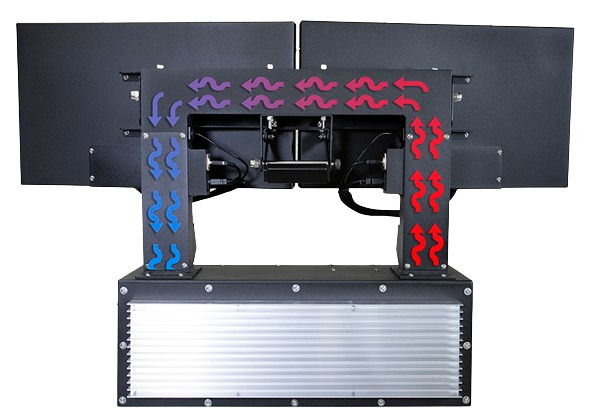

The aluminum monitor support also serves as a heat sink. Cooling fans in the controller circulate air through the tube and radiate heat out of the computer chamber.

We offer single and dual monitor controller configurations that include a variety of screens available which range from 20" to 27" across.

FOLLOW US ON SOCIAL MEDIA!