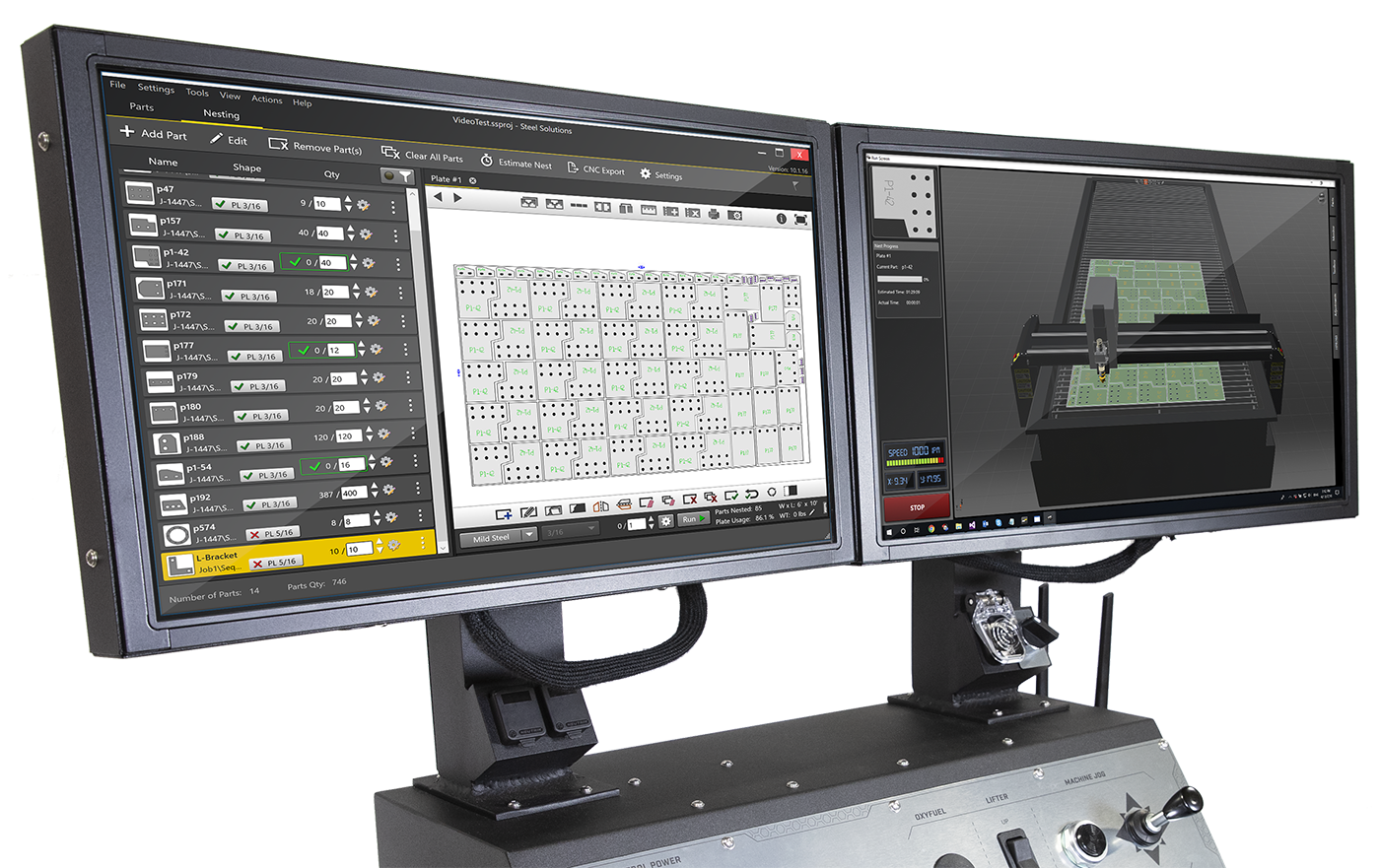

Advanced Machine Controllers for Plasma Cutting & CNC Systems

Revolutionary New Controller Design

Decades of experience and dedication went into designing a new controller that will break the mold of traditional steel processing by allowing for more possibilites than ever before. Our controller offers multi-torch cutting, drilling, and 5-axis bevel cutting with the capability of expanding to even more processes. With an interactive 3D interface that's uniquely designed for each specific machine, you can view machine progress and diagnostics in real-time.

Unmatched Capabilities

Multi-Torch Cutting

Auto tool-spacing with either a pneumatic / electrical clamping system or driving each carriage with it's own motor allows for variable spacing nests.

Drilling / Milling / Tapping

Our new platform comes loaded with advancements in drilling performance. Our easy-to-use program comes with a database loaded for ridged tapping, countersink, counter bore and even some simple milling.

5 Axis Bevel Cutting

We have taken plate beveling to a new level of accuracy with our laser plate-mapping technology. Automatic bevel calibration keeps the bevel system precise and reliable.

Next-Gen Software

Automatic plate nesting on the machine, an interactive 3D interface, and unmatched capabilites push our machine software past the competition. Click below to learn more.

View Our Software

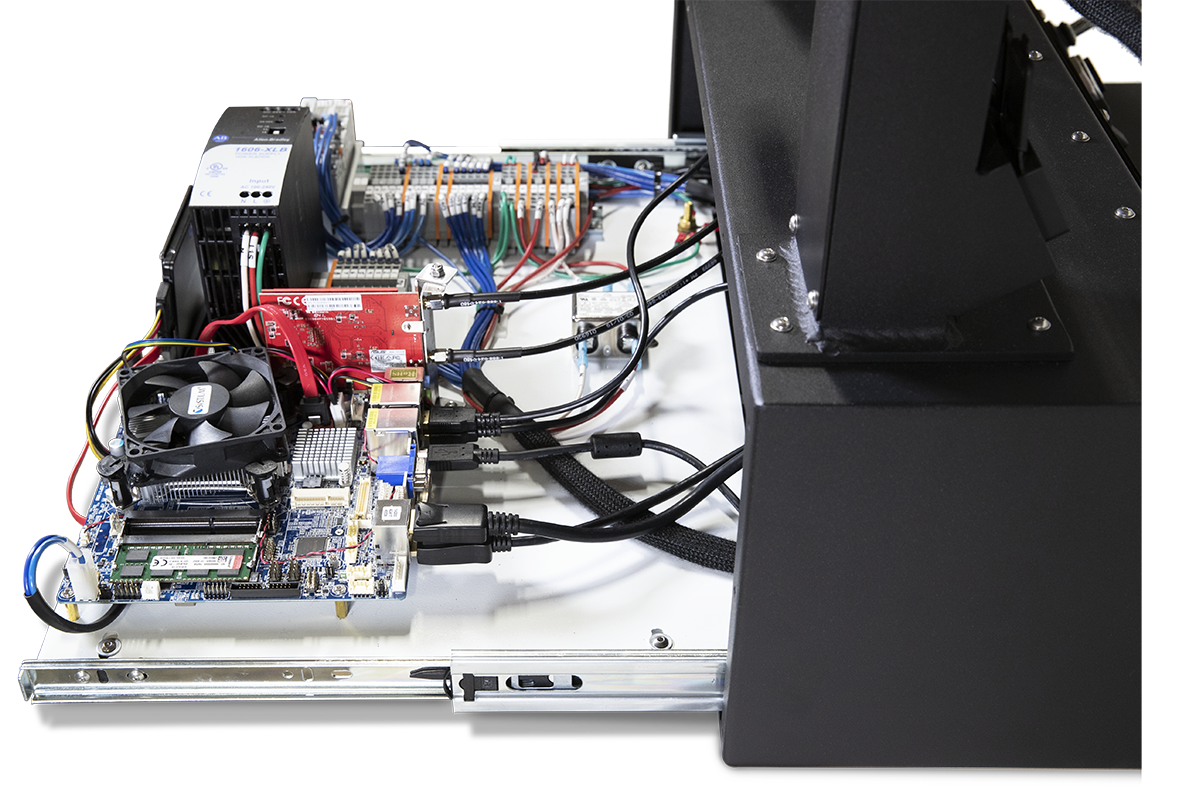

Slide-Out Components

The slide out panel, which is unique to our console, simplifies any repairs or upgrades that may need to be done on the controller. If necessary, the entire panel can be quickly swapped out to easily handle upgrades in the future.

Cooling Fans

The aluminum monitor support also serves as a heat sink. Cooling fans in the controller circulate air through the tube and radiate heat out of the computer chamber.

Touchscreen Monitor

We offer single and dual monitor controller configurations that include a variety of screens available which range from 20" to 27" across.