Products / Drill

Our New Drill Line-Up

Our new drill system line-up includes 2hp, 10hp, and 20hp units. Our extremely versitile drills process high quality parts by utilizing carbide drilling, helical milling, and rigid tapping abilities.

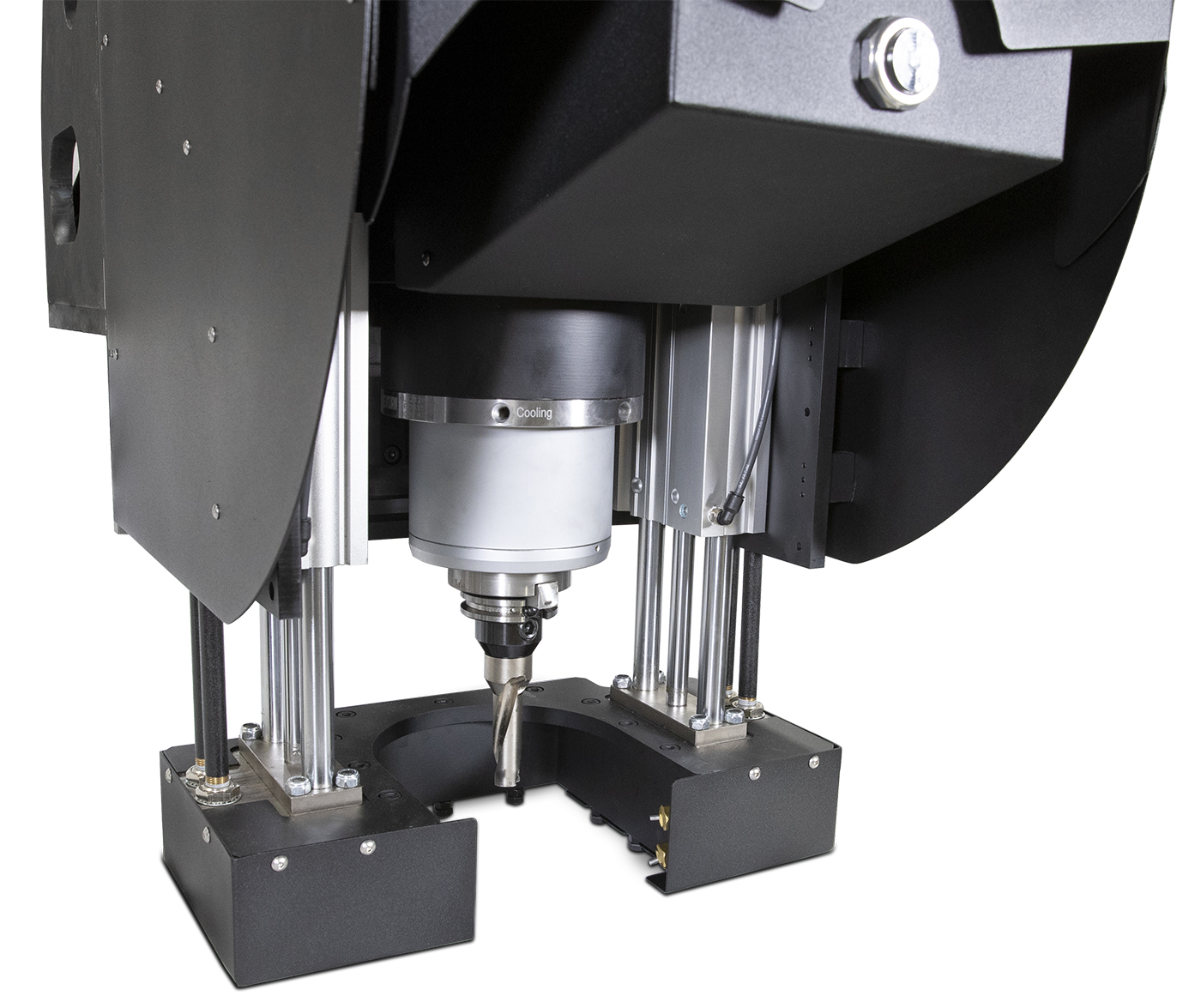

Carbide Drilling

Precision carbide drilling gives you accurate holes even for the lowest tolerances. Our 10hp unit drills up to 1-1/2" diameters with proper tooling.

Helical Milling

Process accurate slot and counterbore operations with consistent results every time using the helical milling feature.

Rigid Tapping

Rigid tapping synchronizes feed and rotation to give you smooth bolt-ready holes with clean threads from start to finish.

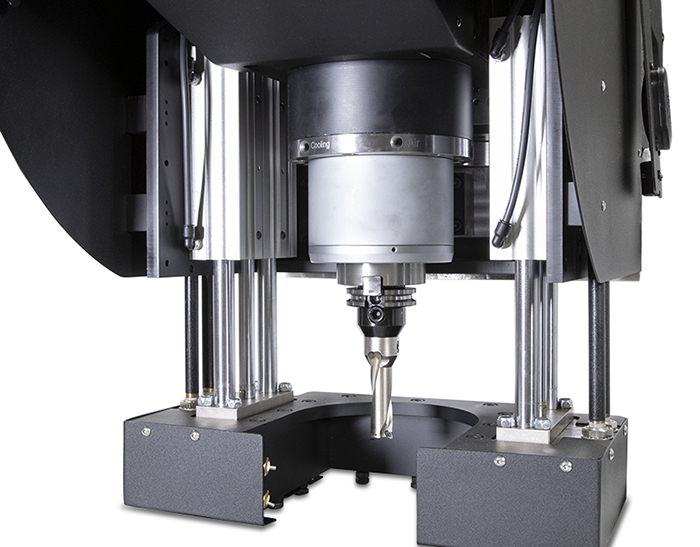

Heavy Duty Construction

Our drilling units are heavily constructed for the toughest enviroments of steel fabrication shops across the country. No detail was overlooked in designing a brand new drill system that would produce consistant and reliable results all while simplifying the maintenance process and preserving the longevity of the drill.

Powerful Motors

Available in 5, 10, and 20 hp units, the robust motor is built to power through the toughest jobs while maintaining a high level of production. Our goal was to design a drill that would meet the needs of fabricators in just about any situation.

- CAT 40 Spindle

- Tool change ready

- Pressure foot to hold material

- Tool loaded inputs

Unmatched Part Quality

With the ability to drill, mill, and tap with precision and accuracy, our new drilling system produces high quality parts time and time again. When combining the new drill with our advanced beveling system, the possibilities are pushed far beyond those of a standard plate cutting machine.

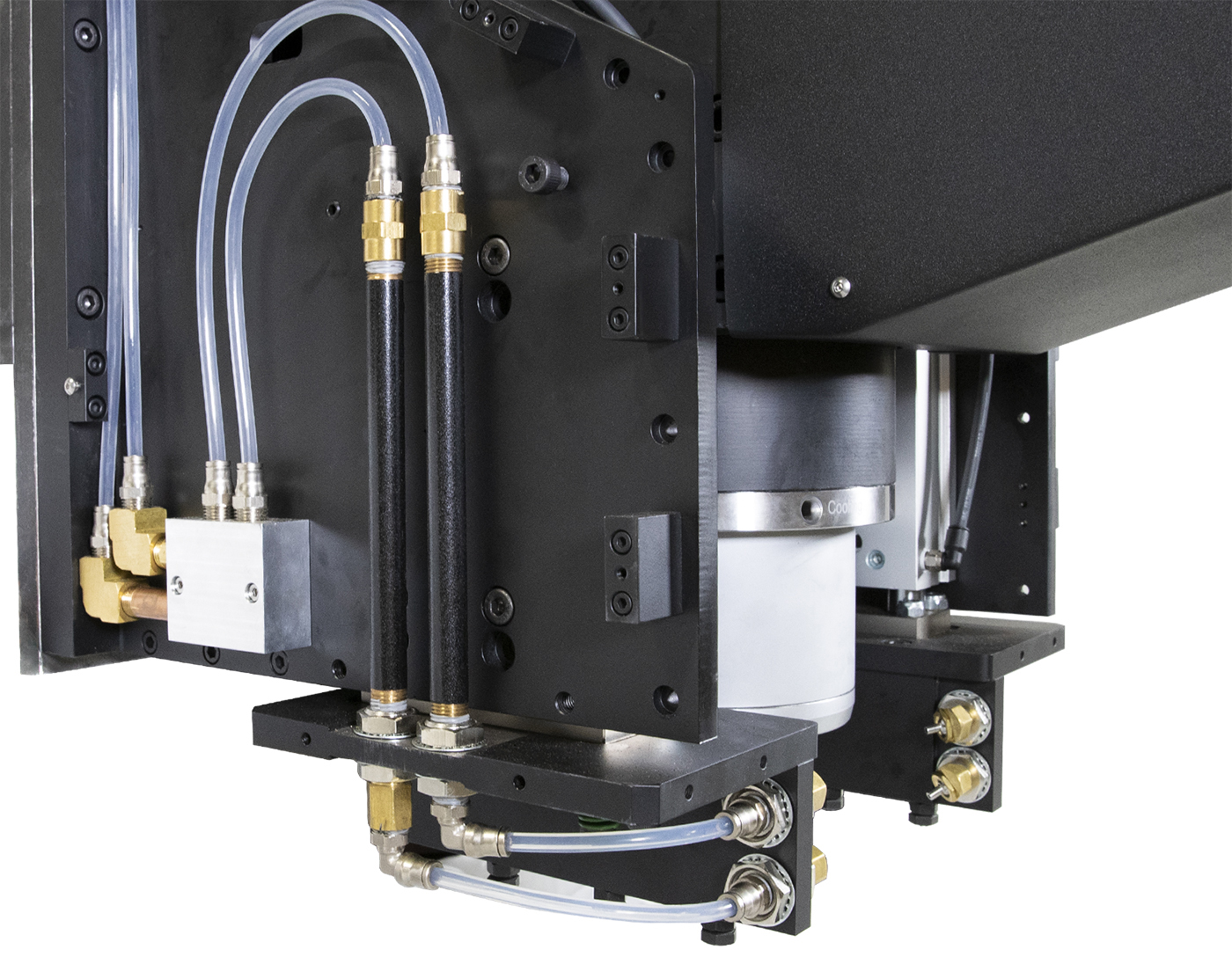

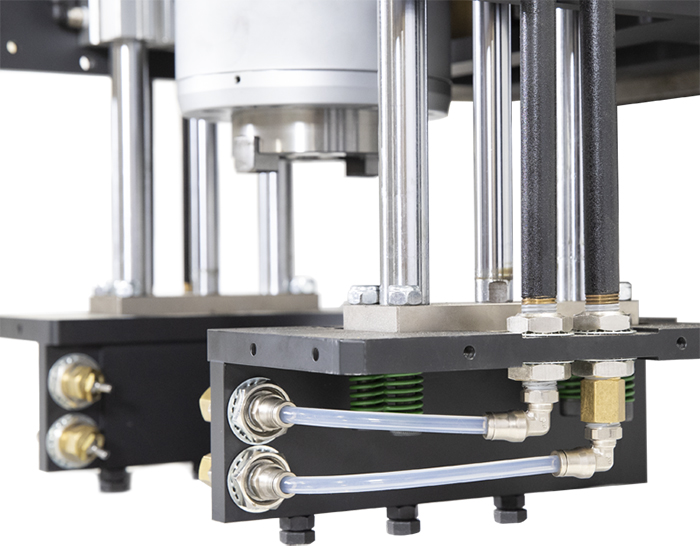

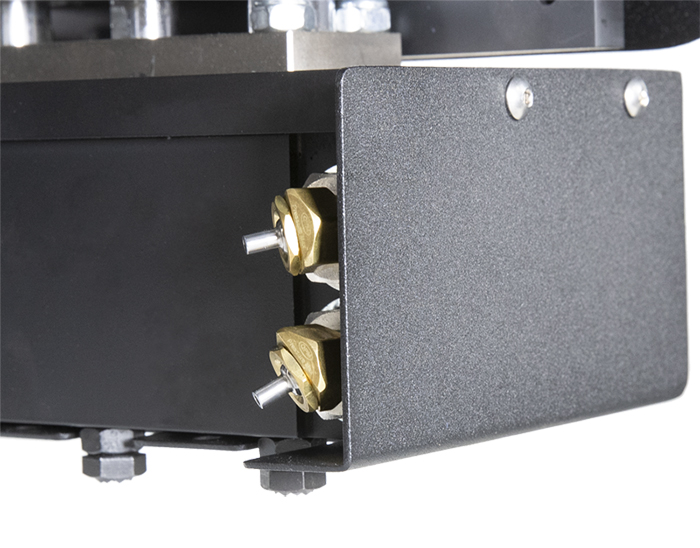

Built-In Coolant System

The built-in coolant and lubrication system is designed to preserve the life of your tooling while ensuring quality drilling. Flood coolant is sent from multiple nozzles that are placed at different angles depending on the current process being used (drilling, milling, tapping). Through-spindle coolant is sent through the tool at up to 300 psi allowing for heavier drilling, higher feedrates, and better part quality.

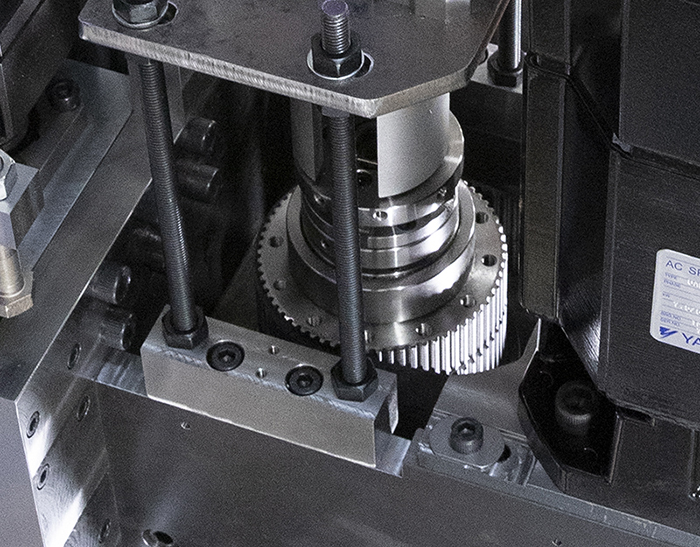

Ethercat Spindle Drive

The performance and power needs of heavy duty drilling are met with the ethercat spindle drive. This Yaskawa drive gives you high torque across a large range of speeds.

- 10000 rpm spindle motor

- Reduced 1.7:1 for drilling power

- Pneumatic drawbar

- cat 40 spindle

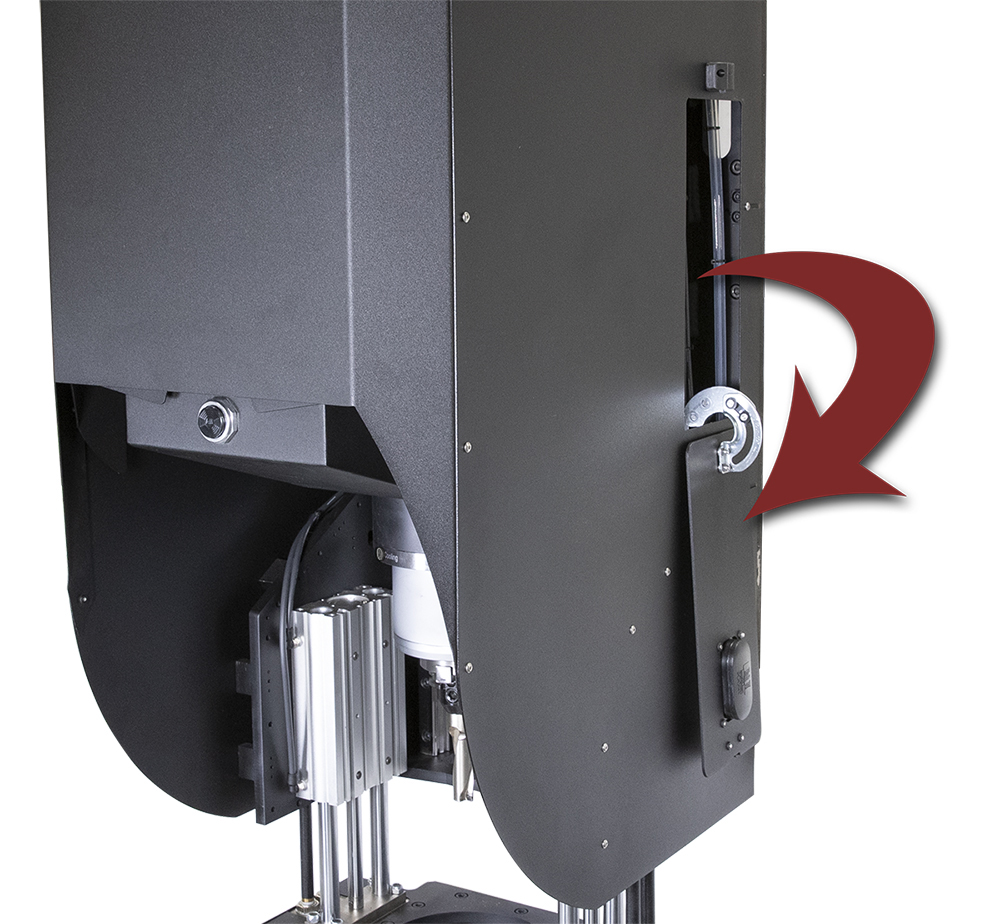

Access Panels

Access panels are located on each side of the drill cover. These panels make it much easier to perform maintenance on the drill when the bearings need to be lubricated.

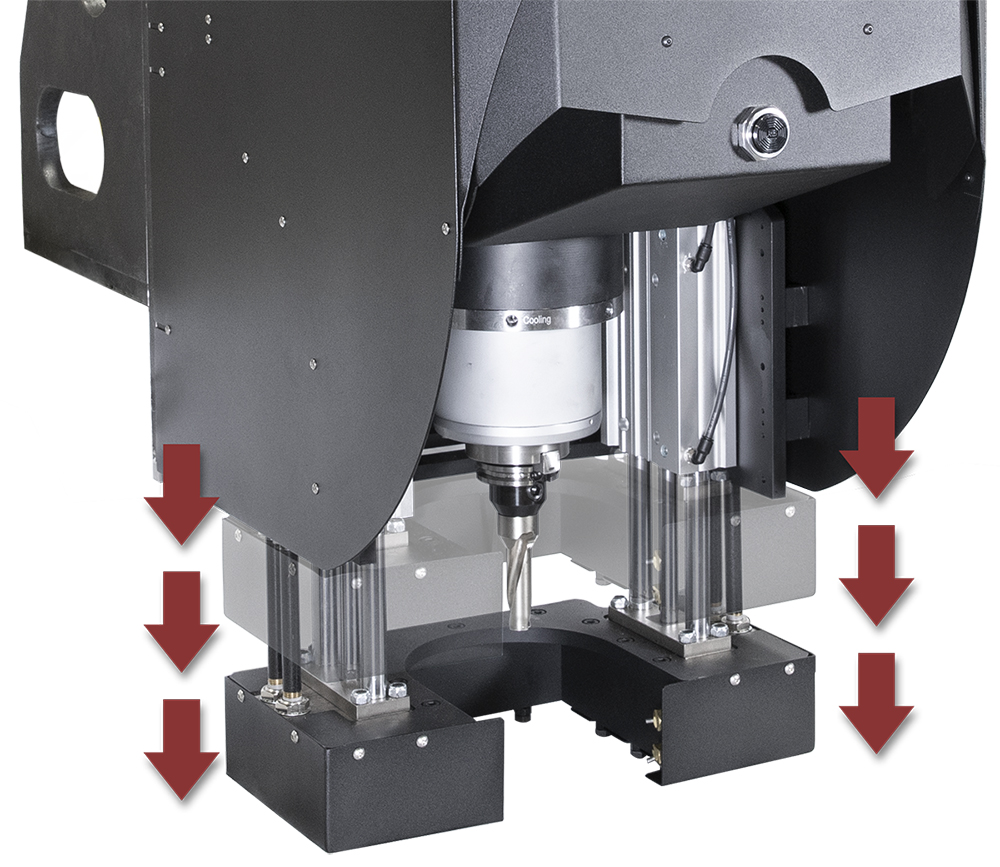

Plate Stabilizer

While drilling and tapping, the plate stabilizer will extend down to hold the material in place. The stabilizer will stay retracted during milling to allow the drill to move freely.